Air compressor heat recovery energy saving renovation project

Product Description

Air compressors consume large amounts of electrical energy in industrial production, and according to the U.S. Department of Energy, air compressor systems account for approximately 10-30% of industrial electricity use (U.S. Department of Energy, 2003). However, more than 90% of this electrical energy is ultimately converted to heat and dissipated into the environment (Çengel & Turner, 2005). Air compressor heat recovery technology can significantly improve energy utilization efficiency and reduce business operating costs by recovering this waste heat for production or domestic hot water, space heating, and other uses. Domestic studies have shown an average payback period of 1-2 years for air compressor heat recovery projects.

Approximately 65-75% of industrial air compressors are suitable for heat recovery, subject to evaluation:

1) Model and Power

2) Operating conditions >4000 hours/year, prioritized annual operation >6000 hours

3) Heat demand matching

The degree of heat demand matching directly affects the economic benefits of heat recovery projects, and there are obvious regional differences in between. A comparative analysis by the Building Energy Efficiency Research Center of Tsinghua University (2018) shows that the payback period in the northern region is 20-30% shorter than that in the south due to the high demand for heating, while industrial hot water demand in eastern China is stable, and the system utilization rate is the highest.

The heat recovery program is mainly applicable to air compressor models: micro-oil screw air compressors, dry oil-free screw air compressors, centrifugal air compressors, refrigeration chiller.

Piston compressor: need to modify the cylinder cooling system, recovery is more difficult

Micro compressors (<7.5kW): value of recovered heat is less than the cost of retrofitting. Preferably 50kW or more, the higher the power the higher the recovery value.

Variable frequency air compressor: 30-50% reduction in heat recovery system efficiency during large load fluctuations

Water-cooled compressor: additional heat exchanger required, 40% longer payback period

The modification of scroll air compressors by Hanzhong Precision Machinery (2022) shows:

- 55% recovery efficiency with the addition of an oil line heat exchanger

- However, the payback period was extended to 28 months

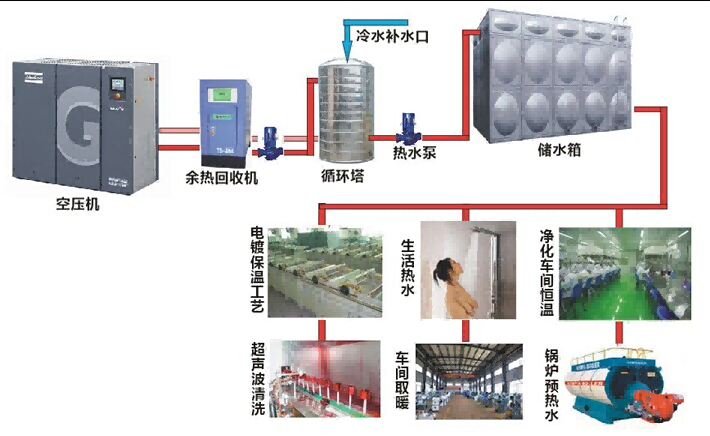

Air compressor (air compressor) is one of the more important production power in industrial production, air compressor in the work of the project consumes most of the electrical energy will be converted into compression heat, these heat energy usually through the cooling system of the cooling in the atmosphere for nothing.

The heat recovered from the air compressor heat recovery system can be used to heat hot water, which can be used for employee showers or space heating, as well as for process manufacturing. The hot water can be used for boiler pre-feeds or directly in processes that require high temperatures, saving the user the high cost of natural gas or other fuels.

According to the theoretical basis of air compressor design, combined with engineering thermodynamics, the compressor in the compression process of constant temperature compression is the most energy-saving, which not only reduces the consumed energy, but also reduces the temperature of the compressed gas, so that the operation of the compressor is more reliable.

Air compression process is approximated as an adiabatic compression process, the compressor in order to make it as close as possible to the constant temperature compression process, the general use of air-cooled and water-cooled cooling methods, while the rotor between the realization of the sealing and lubrication of the bearings, in order to ensure that the compressor is efficient, safe operation, we try to make the compressor operating temperature control in the smaller magnitude of the temperature control in the 100 ℃ below the guaranteed energy-efficiency.

Absolute Energy of Compressed Air - Enthalpy, Enthalpy (kJ) : Indicates the energy contained in a liquid or gas. According to thermodynamic theory, the absolute energy of flowing air consists of enthalpy, kinematic energy and potential energy. Among them, the kinematic and potential energies are so small that they are basically negligible, while the enthalpy consists of internal energy and transfer energy. Therefore, the absolute energy of air depends on the mass and temperature of the air and is independent of the pressure. Even air in an atmospheric state contains a large amount of enthalpy.

When the air is compressed, the enthalpy of the air (sensible heat) increases with the work done by the mechanical energy, from which it can be understood that the thermal energy of the air compressor comes from the movement of the air molecules friction and mechanical friction to produce thermal energy, assuming that the specific heat is constant, if the compressor outlet temperature is the same as the inlet temperature of the initial state, the energy in the compressed air is the same as the energy before compression.

Therefore, the heat recovery system in operation can theoretically be regarded as 100% recovery of electrical energy while getting free compressed air. But in fact, the compressor in the process of operation, the machine surface radiation heat dissipation and heat transfer process of the heat emitted can not be recovered.

Product Specification

What is lost if the heat of compression is not recovered?

The energy consumed by an air compressor is converted into heat at a staggering 94%. Without energy recovery, this expensive heat energy would disappear into the atmosphere through cooling systems and radiation. Energy recovery recovers a significant portion of this heat and uses it from new, resulting in significant energy savings. The actual savings depend on your compressor equipment, air system and waste heat application.

What does it mean to recover heat from a compressor?

This means you can reduce or even eliminate the boiler and its equipment that generates heat or steam for industrial processes. You can save money on installation, maintenance, energy and carbon emissions.

Typical industry economic efficiency data

1. Textile industry

A study of a textile group in Jiangsu Province by a team from Donghua University showed (Wang et al., 2021):

Installation of four 132kW air compressor heat recovery systems

Total investment $480,000

Annual heat recovery 2.1×10⁶MJ

Replacement of steam boilers saves 182 tons of standard coal per year

Payback period 11.8 months

Carbon dioxide emission reduction up to 476 tons/year

2. Automobile manufacturing

GAC Technology Center Report (2022):

Heat recovery system for preheating of electrophoresis drying lines

Total power of air compressor 560kW

System thermal efficiency up to 78

Annual natural gas cost savings of $860,000

Dynamic payback period of 14.2 months

3. Pharmaceutical industry

Included in the China Pharmaceutical Engineering Design Association Casebook (2020):

North China Pharmaceutical Plant Heat Recovery Project

Adoption of "air compressor + chiller" combined heat recovery system

Comprehensive energy utilization rate increased to 82%

Annual operating cost savings of $1.54 million

Project internal rate of return (IRR) of 112%

Product Features

(1) According to the air compressor start-stop synchronization, realize interlocking linkage with the compressor;

(2) Real-time monitoring of the compressor operating temperature, to realize the temperature is too low, too high protection;

(3) Monitor and control the compressor cooling system to balance the optimal compressor temperature;

(4) Compressor fault monitoring and alarming;

(5) Monitoring, protection and alarming of energy recovery heating systems;

(6) Equipment and system fault storage function;

(7) Frost protection;

(8) Realization of IOT management;

Applicability of heat recovery technology for air compressors 1. Applicable air compressor type

Heat recovery technology is mainly applicable to the following air compressor types (China General Machinery Industry Association, 2023):

1)Screw Air Compressor: Best suited for heat recovery, as the oil cooling system removes about 78% of the waste heat (Özgür, 2009).

2)Centrifugal Air Compressor: Recoverable aftercooler heat (approx. 15-25% of input power)

3)Piston Air Compressor: Requires modification of cylinder cooling system, recovery is difficult

2. ExclusionsThe following air compressor types have poor heat recovery economics (GB/T 38549-2020):

1)Micro Air Compressor(<7.5kW): value of recovered heat lower than retrofit cost

2)Variable Frequency Air Compressor: Heat recovery system efficiency decreases by 30-50% with large load fluctuations (Wang et al., 2021)

3)Water-cooled Air Compressor: Additional heat exchangers required, 40% longer payback period

3. Key conditions of applicationEven applicable models need to be met (Hopi General Hospital Report, 2019):

Running time: >4000 hours/year

Load factor: >60%

Oil temperature: >70℃

4. Special model retrofit cases

The modification of scroll air compressors by Hanzhong Precision Machinery (2022) shows:

- 55% recovery efficiency with the addition of an oil line heat exchanger

- However, the payback period was extended to 28 months

reach a verdict

Approximately 65-75% of industrial air compressors are suitable for heat recovery, subject to evaluation:

1) Model and Power

2) Operating conditions

3) Heat demand matching

Retrofit cost per kW for heat recovery in air compressors

Based on literature data and actual cases, the cost per kW of heat recovery for air compressors is in the range of $600-4000, and the payback period is generally shortened to 1-2 years.

+86 13917986725

+86 13917986725