Shimadzu AGS-V Static Universal Material Testing Machine

Product Description

Shimadzu AUTOGRAPH AGS-V Series

Static universal material testing machine

safety cover

Blocking of flying specimen fragments

A safety cover is provided in front of the test space.

High-performance, durable polycarbonate safety guards effectively block specimen debris for effective operator protection.

Interlocking device to prevent accidental operation

With an interlock function, test and return operations cannot be performed when the safety guard is open, thus reducing the risk of accidents.

Upper and lower safety guards with stay-anywhere function

The safety guard can stay in any position.

Smart Beam

Fixture collision prevention

The intelligent beam recognizes the current position in real time. In case of misuse of the fixtures too close to each other, the system immediately issues a collision warning.

Automatically stops the beam.

Contact detection and instantaneous emergency stop

When adjusting the position of the test fixture or mounting the specimen, the system continuously monitors the test fixture even when the safety guard is open to operate the beam.

Viewing status. In the event of a change in test force due to fixture or hand contact, etc., the beam will immediately stop in an emergency, ensuring that the operation will not be interrupted.

Security.

Overload detection function

The beam will automatically stop once it detects that the test force exceeds the rated capacity of the load cell. This reduces the trim knob

Risk of damage to the load cell due to overload during operation and test runs. (Note: Damage to the

(Possibility)

Travel limit switches

Press, position, release

Travel limit switches are used to limit the range of movement of the beam and prevent collision between the beam and the fixture. The spring mechanism within this switch that

The ability to secure the switch in the hand release position prevents setting failure caused by operational errors (e.g., forgetting to lock, etc.).

Pursuit of easy-to-use operator interface

Equipped with a color LCD touch panel that displays appropriate buttons and information according to test conditions. Various operations such as adjusting the fixture spacing before the test and confirming the measured value during the test are realized, and information display is supported to enhance portability.

Self-diagnostic function of the instrument

Real-time monitoring of the calibration information of the sensor amplifier, the operating status of the testing machine, the power supply voltage and the communication status, etc., and instant notification of abnormalities. At the same time, the instrument automatically records the length of use and the number of times, and reminds maintenance when it reaches the set value, which helps to grasp the maintenance time and effectively reduces the downtime caused by failures.

Select Display

During the test, the test values can be displayed in a format that is easy to view. If the test values are set to be displayed on two lines, the operator can confirm the test values even from a distance.

Portable control without a computer

Operate only the controller, no need for a computer, easy to carry out the test

-Touch panel can be directly set tensile, compression, bending test conditions.

Multifunctional workbench

Multi-functional workbench for placing test tools and specimens.

Minimizes operator movement for efficient testing.

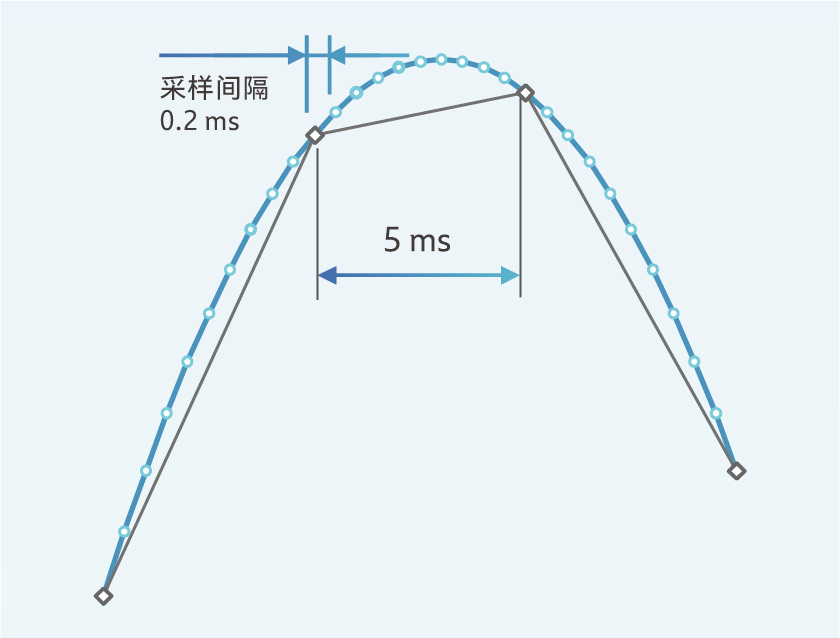

High-speed data sampling: 5 kHz

The high-speed sampling function has been improved from 1 ms to 0.2 ms.

Quick and small changes can be recorded.

Product Specification

Wide range of test speeds with high speed beam return

The test speed range of 0.0005~1500 mm/min allows testing under a wider range of test conditions. In addition, the crossbeam

The return speed has been increased to 1650 mm/min, helping to shorten the customer's test time.

Load accuracy guarantee range: 1/1000

The load accuracy guarantee range has been expanded to 1/1000, and the accuracy guarantee interval has been expanded as well. Accurate measurement is possible even at the initial stage of a test. Previously, it was necessary to replace multiple sensors depending on the load. Today, fewer sensors can correspond, thus reducing the cumbersome process of replacement and providing customers with a more efficient and portable experience.

Multifunctional workbench

High-speed sampling function upgraded from 1 ms to 0.2 ms

Product Features

Shimadzu Corporation has been manufacturing testing machines for more than 100 years, and we have always been committed to working together with our customers.

The new AUTOGRAPH helps testers work safer and more efficiently every day.

AUTOGRAPH AGS-V, side by side with our customers!

+86 13917986725

+86 13917986725