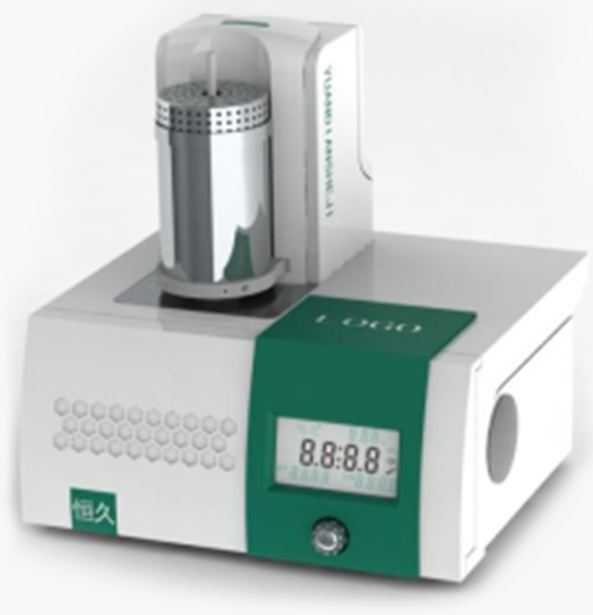

HQC Automatic Differential Heat Analyzer

Product Description

Fully Automatic Differential Heat Analyzer

An instrument for measuring the temperature difference between a substance and a reference as a function of temperature under programmed temperature control.

Instrument Usage

It mainly measures physical and chemical changes related to heat, such as changes in the melting point of a substance, heat of melting, heat of crystallization and crystallization, heat of reaction of phase change, thermal stability (oxidation induction period), and glass transition temperature.

Instrument Features

Integration of the capacitive electro-mechanical and atmosphere control into a single instrument reduces signal loss and interference.

Atmosphere control system adopts mass flow controller, two-way stabilized pressure, stabilized flow gas can be automatically switched in the experimental process, high precision, good repeatability, fast response speed (can be customized to resist a variety of corrosive gases atmosphere control system).

The whole measurement process is completed automatically, and automatic drawing, the use of software functions can be completed DTA routine data processing; special data processing (DTA peak area, enthalpy calculation, kinetic parameter calculation, data comparison, a variety of algorithms to calculate the activation energy, glass transition temperature, comparative method of measurement of specific heat, etc.).

The system can take a screenshot at any moment during the acquisition of the specimen and automatically change the range according to the size of the output signal.

Users are able to calibrate the accuracy of the instrument's temperature and energy using standard specimens such as indium, tin and lead.

Large screen LCD display, real-time display of the instrument's status and data, two sets of temperature-measuring couplings, one set of couplings real-time display of the furnace temperature (regardless of whether the furnace is working or not), and the other set of couplings to display the temperature of the sample at work.

Users give the formula or calculation method, our company can provide the corresponding software development products in time.

Self-developed thermostatic controller, thermostatic gas chromatography, mass spectrometry connectors, thermostatic band, can fully guarantee the secondary detection of tar and various reaction gases.

Product Specification

Controllable automatic lifting and lowering of the furnace body for accurate positioning and improved measurement repeatability

LCD screen real-time display of furnace temperature and sample temperature, gas circuit status, etc.

With oxidation induction period test and analysis software

Constant temperature for 72 hours at any one temperature point in the temperature rise range

With crystallization kinetics calculation function and step-cooling curve plotting function

DSC data

DSC measurement range: ±1mW~±500mW

DSC accuracy: ±0.1μW

Temperature data

◇ HQC-1: room temperature~1150℃

◇HQC-2: Room temperature~1250℃

◇ HQC-3: room temperature~1450℃

◇ HQC-4: room temperature~1550℃

Temperature accuracy: ±0.1℃.

Temperature rise rate: 0.1℃/min~100℃/min (customizable)

Vacuum degree (after optional vacuum unit): 2.5×10-²pa

Atmosphere system: Mass flow controllers are used (atmosphere systems resistant to various corrosive gases can be customized)

Constant temperature controller; gas chromatography, mass spectrometry connectors; constant temperature band (optional) Constant temperature range: room temperature ~ 200 ° C

Differential thermal data (DTA)

Measuring range: ±10μv~±2000μv (no range control)

DTA resolution: 0.01μv

DTA noise: <0.01μv

Crucible:

Standard configuration: ceramic crucible 0.06 ml or 0.12 ml

Select Configuration: Aluminum Crucible, Graphite Crucible, Quartz Crucible, Platinum Crucible

Product Features

HQC automatic differential thermal analyzer any temperature point can be a long time constant temperature, two sets of temperature measurement coupling.

+86 13917986725

+86 13917986725