BPN Series Carbon Dioxide Incubator

high class

high class

Product Description

Touch Screen Controller

Adopting large touch panel screen to replace the traditional key operation mode, easy to operate and program editing. Controller operation interface is available in English and Chinese.

●Displays the instantaneous operation curve, with curve summary function, can directly view the same time period temperature, humidity, CO2

Changes in the three sets of concentration curves and information on abnormal alarms and door opening and closing.

●After the data and test conditions are input, the controller has a screen lock function to avoid abnormal shutdown due to human touch.

● 72-hour machine operation record query function, which is convenient for users to trace the abnormal situation and trace back the historical operation information.

Optional RS-485 communication interface allows you to design programs, monitor the experimental process and perform functions such as switching on and off on a computer;

CO2 concentration control system

●Imported infrared (IR) sensor control

If you need to open the door frequently in the process of experiment, infrared sensor is the best choice. The imported infrared ray (IR) sensor chosen by Yiheng is very sensitive to the change of CO2 concentration, and it is not affected by other conditions inside the incubator, with high measurement accuracy, avoiding the influence of temperature and humidity inside the box when monitoring CO2 concentration by traditional thermal conductivity probe. If the door is closed after opening for 30 seconds, it can be restored to 5% of the set CO2 concentration in ≤3 minutes, even in the case of multiple users and frequent opening and closing of the door, the CO2 concentration inside the box can still be kept fast, stable and uniform.

O2 concentration control system (optional)

● The use of zirconia O2 concentration sensor, product linearity, long service life, can provide accurate and stable O2 concentration control;

The O2 concentration control range is 1~90% (minimum 0.1%), realizing that a three-gas incubator can satisfy both high-oxygen culture, low-oxygen culture, and microaerobic culture;

Temperature control/detection systems

A. Incubator temperature control system

Pt100 temperature detector to ensure accurate temperature inside the box. It can be realized by the difference between the actual temperature in the box and the set temperature.

Adjust the heating power at the time to ensure the accuracy of the actual temperature in the box. Can be 3 minutes after the user opens and closes the door to take and release samples

The experimental temperature was restored within.

B. Door temperature heating system

The outer box door has a heating function, the door temperature follows the box temperature and is slightly higher than the box temperature, which can effectively prevent the glass door from generating condensation, facilitate the observation of the experimental process, and avoid the possibility of microbial contamination due to the generation of condensation from the glass door.

C. Ambient temperature monitoring system

Independent ambient temperature detector, according to the changes in the ambient temperature in the experiment to automatically adjust the CO2 incubator heating system to avoid overshooting the temperature inside the box.

D. Over-temperature protection system

Independent of the CO2 incubator temperature control system outside the backup temperature control system, when the incubator temperature control system failure caused by the temperature out of control, the temperature inside the chamber reaches the temperature limit set value of the controller, the over-temperature protection system will automatically cut off the heating, and sound and light alarms.

E. Power failure alarm system

Real-time detection of the power supply status of the incubator, when power failure and power loss occurs, it will immediately send out sound and light alarm signals, so that the incubator is safe and reliable operation without accidents.

Sterilization systems

●90°C high temperature moist heat sterilization system (RHP)

● It is possible to sterilize the inner chamber (including the temperature sensor, carbon dioxide concentration sensor, fan, partition, and stand) with high temperature and humidity, eliminating microbial contamination caused by bacteria, molds, mycoplasma, and other microorganisms in cell culture, and providing a safe experimental environment for users;

:: Simple operation: the user simply presses the (Sterilization Start) button on the control panel, and the sterilization system sterilizes all parts of the chamber, including temperature sensors, carbon dioxide concentration sensors, fans, partitions, and brackets. The entire sterilization process takes up to 18 hours to ensure complete sterilization;

UV sterilization system (RWP)

● The ultraviolet germicidal lamp is located at the top rear side of the chamber, which can regularly sterilize the interior of the chamber and effectively kill floating bacteria in the circulating air of the chamber and the water vapor in the humidifying water tray or the bottom slope water tray, thus effectively preventing the contamination of the cell culture during the period;

Independent temperature/CO2 concentration monitoring system (optional)

●Optional external independent temperature and CO2 concentration monitoring system can be equipped to realize dual monitoring of temperature and CO2 concentration inside the chamber.

Filter systems

A. Microbiological filters

● The CO2 air inlet is equipped with a microbiological high-efficiency filter, which has a filtration efficiency of 99.99% for particles with a diameter of ≥0.3μm, effectively filtering bacteria and dust particles in the CO2 gas.

B. HEPA filter

● CO2 incubator gas quality is an important indicator of the cell culture environment, HEPA filter can effectively filter out bacteria and dust particles in the outside air, eliminate and prevent cross-contamination between the outside air and the incubator chamber, so that the incubator is always in a sterile state, HEPA filter is easy to dismantle and install, no tools required;

safety function

●Temperature high, low and over-temperature alarms ●Cabinet temperature sensor failure alarm ●Door temperature sensor failure alarm

● Over-temperature sensor failure alarm ● CO2 concentration too high or too low alarm ● Power failure alarm

●Independent temperature limit alarm ●Long door opening time alarm ●Sterilization and disinfection status indication

Automatic cylinder switching device (optional)

Optional cylinder automatic switching device, the CO2 inlet and N2/O2 inlet are connected to the A/B cylinders respectively, which can be automatically switched to ensure the continuity of air intake;

Hierarchical rights management (optional)

Multiple assignable personal accounts, according to the needs of equipment management, the equipment controller operating privileges can be assigned to the administrator, operator, visitor three privilege level accounts. The touch screen also supports Chinese and English inputs, and the system can be logged in according to the actual name of the operator. At the same time, the system also has an operation log query function, which records the detailed operation logs of each user, making it convenient for the operation and maintenance management of the equipment and audit trails;

Wireless Alarm System (SMS Alarm System) (Optional)

● If the equipment user is not on site, when the equipment malfunctions, the system promptly collects the malfunction signal and sends it to the cell phone of the designated receiver via SMS to ensure timely troubleshooting and resumption of the test to avoid accidental loss.

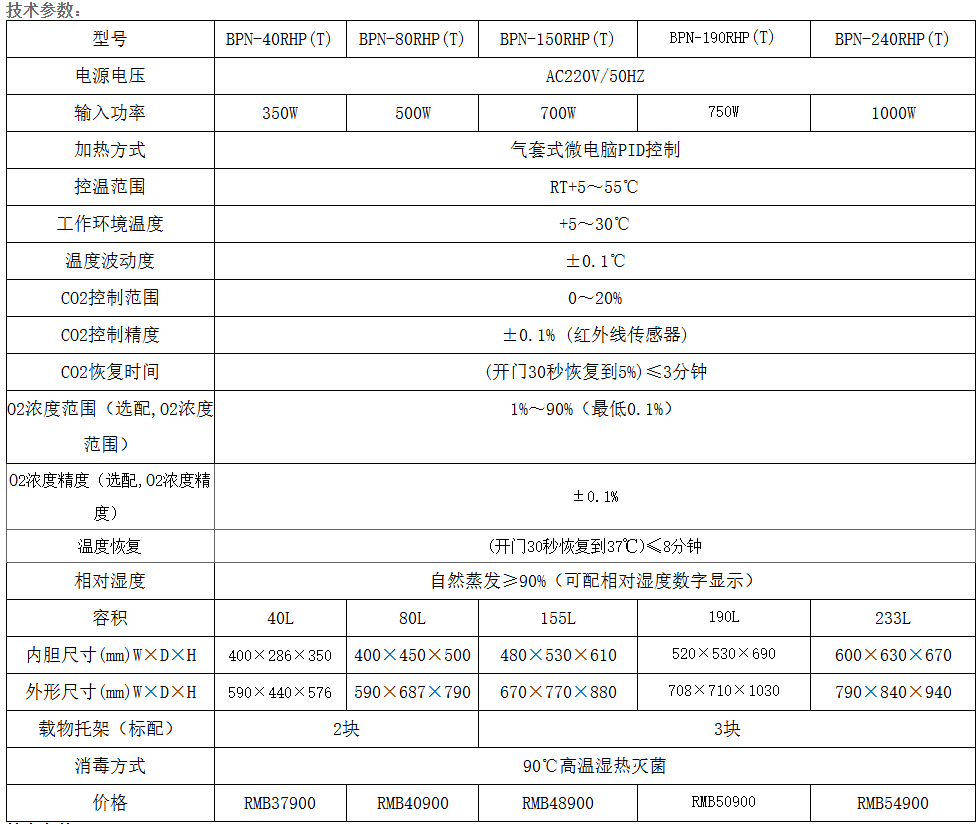

Product Specification

market reference price

See specification chart above

+86 13917986725

+86 13917986725