HR-150A Manual Rockwell Hardness Tester

Product Description

HR-150A Manual Rockwell Hardness Tester Overview:

HR-150A Rockwell hardness tester for the most common type Rockwell hardness tester, widely used in the determination of ferrous metals, non-ferrous metals, non-metallic materials, quenching and tempering and other heat treatment materials Rockwell hardness measurement. Such as cemented carbide, carburized steel, quenched steel, surface hardened steel, hard cast steel, aluminum alloy, copper alloy, malleable castings, soft steel, tempered steel, annealed steel, bearings and other materials.

Integral cast body:

The product body part is molded by casting process, the body is a closed shell, except for the table, screw, manipulation handle exposed, other institutions are installed in the body shell, easy to keep clean. Long-term use of deformation is extremely small, and can effectively adapt to a variety of harsh environments.

Dial readout:

Double scale dial, multi-purpose, can measure HRA, HRB, HRC three kinds of hardness value.

Variable load handle:

Operated by the handle, control the lever to load and unload, without the need to energize the electricity, the test efficiency is high.

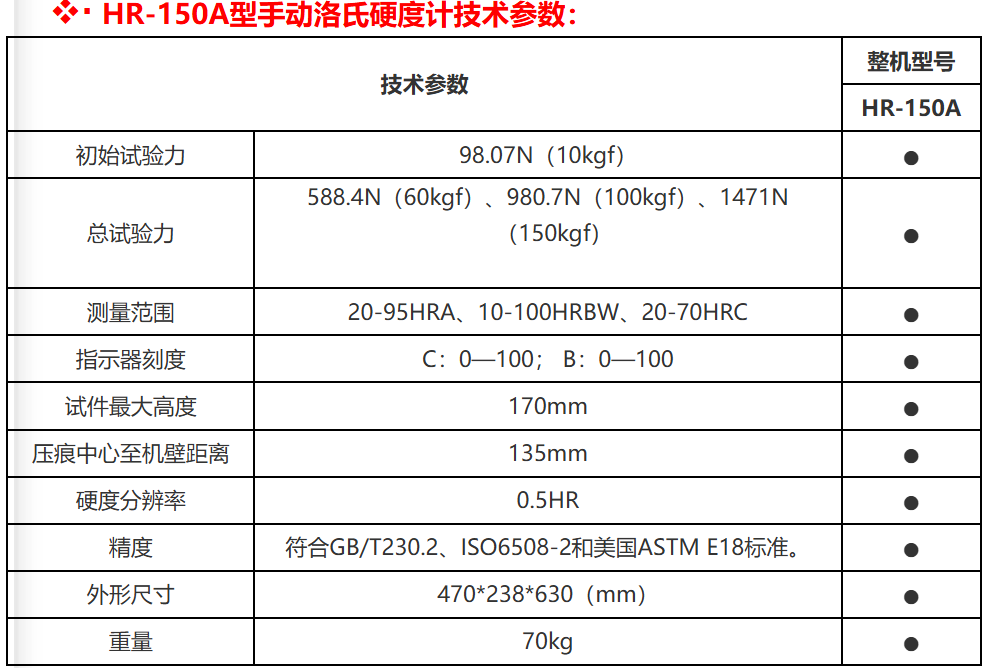

Product Specification

Double scale dial, multi-purpose, can measure HRA, HRB, HRC three kinds of hardness value.

Operated by the handle, control the lever to load and unload, without the need to energize the electricity, the test efficiency is high.

standard configuration

Product Features

No content

| typology | Applicable materials | Typical Application Scenarios |

|---|---|---|

| Brinell hardness (HB) | Soft metals (aluminum, copper), castings, forgings | Quality control in the metallurgical and foundry industries |

| Rockwell hardness (HR) | Steel (HRC), hardened parts, carbide | Hardness testing after machining and heat treatment |

| Vickers hardness (HV) | Thin layers, plating, ceramics, glass | Scientific research, electronic components, surface treatment industry |

| microhardness | Tiny areas (e.g. solder joints, coatings, single crystals) | Materials research, semiconductors, precision manufacturing |

| Hardness on Richter scale (HL) | Large workpieces (pipes, molds), on-site inspection | Maintenance of power and petrochemical equipment |

| Shore Hardness (HS) | Rubber, plastics, elastomers | Tires, seals, shoe soles and other non-metallic products |

| Knoop Hardness (HK) | Brittle materials (ceramics, gemstones) | Jewelry appraisal, ultra-thin material research |

※ Hover over the type of hardness tester to see the test principle.

+86 13917986725

+86 13917986725