TANK MAX Super Microwave Chemistry Platform

Product Description

TANK MAX can operate at a maximum temperature of up to 300°C and a maximum pressure of up to 20MPa, which makes it easy to completely dissolve even difficult-to-solve samples; the single reaction chamber is pre-pressurized, so that samples of different natures and reaction systems can be processed at the same time. No matter what kind of digestion experiments can be coped with freely.

Ultra-high digestion temperature and pressure, so no more inability to digest.

With the maximum operating temperature of 300°C and the maximum operating pressure of 20MPa, conventional samples can be digested more thoroughly, and insoluble samples can also be digested easily and completely.

No need to sort samples, the reaction temperature is identical, more accurate and reliable results.

The single reaction chamber is pre-pressurized, so the digestion tube does not need to bear the reaction pressure, and different samples and reagent systems can be digested at the same time. Moreover, the temperature and pressure conditions of all samples are identical, which makes the digestion process more accurate and reliable, and ensures the reproducibility and traceability of the experiments.

The use of reagents such as aqua regia and hydrofluoric acid is no longer a limitation of the digestion experiment.

Self-cleaning anti-corrosive high-pressure piping design, can withstand most of the reagents including aqua regia, hydrofluoric acid, perchloric acid, the instrument application scenarios more widely.

Rapid heating and cooling to increase the speed of digestion experiments

Adopting single-feeder microwave coupling technology, the coupled microwave field is efficiently fed into the reaction chamber through the large-diameter waveguide port, which results in high microwave energy utilization, uniform distribution of microwave field, faster heating speed and higher degradation efficiency.

No need to drive the acid, and the volume can be fixed directly after digestion, which further improves the efficiency of the experiment.

Only 2mL of acid is needed to complete the digestion of a single sample, and the volume can be fixed directly without the need to drive the acid, which improves the experimental efficiency by more than one times. In addition, the extremely low reagent consumption can significantly reduce the acid gas emission, which is more environmentally friendly.

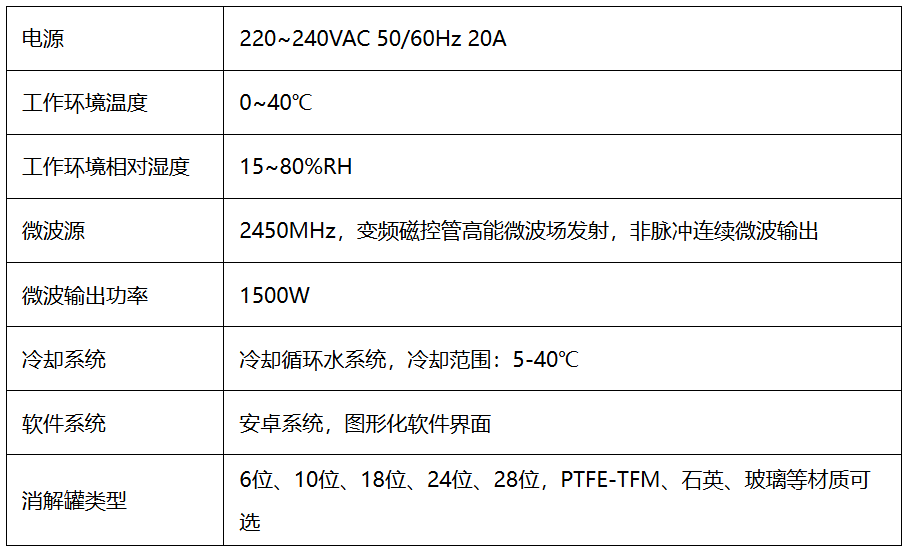

Product Specification

No content

Product Features

Only 2mL of acid is needed to complete the degradation of a single sample, and the degradation can be completed without driving the acid, and the volume can be fixed directly, so the experimental efficiency can be improved by more than 1 times; the degradation tube can be made of PTFE-TFM, high purity quartz and other materials, and the cost is more than 60% lower than that of the microwave degradation tank, and the cost of the tube can be even lower than the cost of the ordinary glass test tube.

Easy Load is designed for easy loading, the ablation tube can be inserted into the cap, and the sample rack and liner tank do not need to be aligned, saving operation time and greatly reducing the error rate; it can realize the whole process of one-key operation, without manual assistance, without software guidance, and enjoy a new experience of automated ablation. Predictive protection mechanism, active safety protection, passive safety protection, acid mist protection and other four-fold safety structure for your experimental safety escort. TANK MAX super microwave, ultra-strong digestion capacity, to bring you ultra-high experimental efficiency, minimalist operation experience, comprehensive safety protection!

+86 13917986725

+86 13917986725