TANK Microwave Digester

Product Description

Microwave digestion technology utilizes the penetrating and activating reaction ability of microwaves to heat the reagents and samples in the closed containers, which can increase the pressure in the digestion tank and the reaction temperature, thus greatly improving the reaction rate and shortening the time of sample preparation. All-around safety guarantee, safety protection and anti-corrosion ability at the same time The furnace chamber is made of industrial-grade 316L stainless steel, sprayed with multi-layer Teflon coating, providing a 5-year warranty commitment; explosion-proof buffer safety door, built-in anti-flow channel to prevent microwave leakage, which can be self-sealing, impact resistance and interlocking linkage device. Aerospace composite fiber outer tank overall sprayed with Teflon coating, pressure resistance up to 70MPa, temperature resistance of 600°C. Dual magnetron frequency control, to ensure the consistency of sample digestion. Two-dimensional space staggered arrangement of dual magnetron frequency control system, high-frequency closed-loop feedback control, to achieve continuous non-pulse microwave output, to ensure a more uniform microwave field in the cavity, higher energy utilization, to ensure the consistency of the sample degradation. Dual liquid crystal display, working status and experimental progress at a glance. Equipped with color touch screen, it can display the experimental status such as temperature, step, time, power, etc. in real time, display the temperature histogram of the whole tank, and view the temperature rise curve of any ablation tank. The video image monitoring system inside the furnace chamber can clearly observe the working image inside the furnace chamber, and the experimental status can be seen at a glance. Pressure control technology for the whole tank Self-discharge tank adopts elastic pressure relief and self-sealing technology, which ensures that the ablation tank is completely sealed without leakage under normal working condition, and automatically and safely discharges the pressure under overpressure condition, releasing the excess reaction gases (carbon dioxide and nitrogen oxides) and sealing it instantly to ensure that the subsequent experiments are carried out smoothly; high-pressure tank adopts the safety pressure relief piece technology, which ensures that the ablation tank is completely sealed without leakage under normal working condition, and automatically completes the pressure relief piece in over-pressure condition to ensure the safe operation. In case of overpressure, the pressure relief piece automatically completes the pressure relief to ensure the safety of operation. Temperature control of the whole tank, precise control and monitoring of abnormalities, to ensure the safety of the experiment and the effect of digestion. Non-contact infrared sensor at the bottom of the tank can monitor the temperature change of the sample solution inside each tank in real time and display it intuitively, and the COT anomaly monitoring system monitors the anomalies in the process of the ablation experiment, stops the microwave emission and alarms in time to ensure the safety of the experiment. The high-pressure tank is also equipped with a multi-core fiber optic temperature control system, which can accurately control the temperature and at the same time avoid the interference of the sensor with the microwave field. "Cloud service" function, free expansion of storage capacity. Data, methods and other information can be stored and shared in the cloud, and the storage capacity can be freely expanded under the premise of ensuring data security. You can also download the latest version of the software from the public cloud server to realize the online update of the system, which comprehensively improves the user experience. More thoughtful design, convenient for your experimental operation. The instrument is equipped with a light identification system, which can be used to observe the light changes from a distance through the visible window and master the machine operation status; a special tool cart is equipped, which can help the experimental staff to put the sample-filled rotor into or out of the furnace cavity easily, avoiding direct contact between the staff and the ablation tank, and guaranteeing the safety of the experimental staff's operation. Optional ion fan can effectively remove static electricity and prevent powder samples from hanging on the wall; optional high sensitivity solvent monitoring, effectively eliminating the safety hazards of the synthetic extraction process. Wide range of applications Microwave digestion technology is the use of microwave penetration and activation of the reaction ability to heat the reagents and samples in the closed container, which can increase the pressure in the digestion tank, the reaction temperature increases, thus greatly improving the reaction rate and shorten the sample preparation time. Microwave digestion is widely used in a variety of fields and is a commonly used digestion technique.

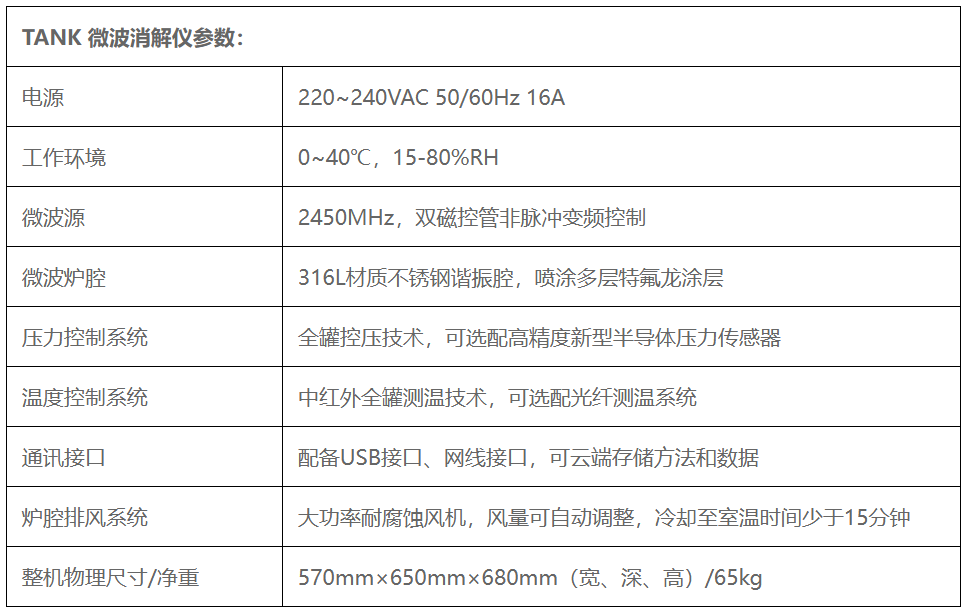

Product Specification

No specification

Product Features

Convenient software operation in compliance with FDA 21CFR Part 11 The instrument adopts Android operating system, which is easy to use and powerful. With functions of electronic signature, hierarchical authority and audit trail, it complies with the relevant regulations of FDA 21 CFR Part 11. The software can automatically recognize the carousel model and perform can counting automatically in order to avoid the tediousness of manual counting and input, making the experiment easier and more convenient.

+86 13917986725

+86 13917986725