Technical Articles

Overview of air compressor heat recovery technology and economic benefits

1. Introduction

Air compressors consume large amounts of electrical energy in industrial production, and according to the U.S. Department of Energy, air compressor systems account for approximately 10-30% of industrial electricity use (U.S. Department of Energy, 2003). However, more than 90% of this electrical energy is ultimately converted to heat and dissipated into the environment (Çengel & Turner, 2005). By recovering this waste heat for production or domestic hot water, space heating, and other uses, air compressor heat recovery technology can significantly improve energy efficiency and reduce business operating costs.

The purpose of this paper is to systematically analyze the economic benefits of air compressor heat recovery technology based on published authoritative research papers to provide data support for enterprise decision-making. All quoted data are from published academic papers or research reports of authoritative organizations to ensure the reliability and objectivity of the analysis.

2. Overview of heat recovery technologies for air compressors

2.1 Technical principles

In the working process of air compressor, electric energy is mainly converted into potential energy and heat energy of compressed air. According to the first law of thermodynamics, the input electrical energy is equal to the output compressed air energy and the sum of the heat energy dissipated. Studies have shown that in a typical screw air compressor, about 15% of the input electrical energy is converted into the potential energy of the compressed air and the remaining 85% is converted into thermal energy (Dallappa et al., 2017). Of this thermal energy, about 4% is dissipated by radiation, 3% is carried away by the compressed air, and 78% is discharged through the cooling system (oil cooler and aftercooler) (Özgür, 2009).

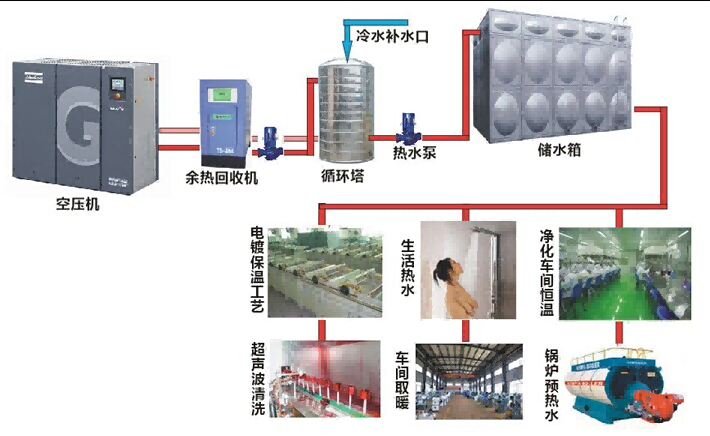

The heat recovery system mainly recovers heat energy through the following ways:

Oil cooler heat recovery: Recovery of about 50-70% of the waste heat

Aftercooler heat recovery: Recovery of approx. 15-20% of waste heat

Integrated heat recovery system: recovers heat from both the oil cooler and the aftercooler at the same time, with a total recovery rate of 70-90% (Kapoor et al., 2019)

2.2 Types of heat recovery systems

Depending on the end use of the thermal energy, air compressor heat recovery systems are divided into the following categories:

1. Air-water heat exchange systems:Transfer of waste heat to water for hot water production or heating. This is the most common type of recovery and is suitable for most industrial environments (Saidur et al., 2012).

2. Air-to-air heat exchange systems:Direct use of waste heat for space heating for locations that require winter heating.

3. Process heating systems:The recovered thermal energy is used directly in production processes such as drying, preheating, etc. (Kaya et al., 2009).

3. Economic benefit analysis of heat recovery from air compressors

3.1 Energy saving potential

Several studies have shown that heat recovery systems for air compressors have significant energy saving potential. Özgür (2009) showed in a study of a textile factory in Turkey that the installation of a heat recovery system in a 160 kW air compressor resulted in the recovery of about 700,000 kWh of thermal energy per year, which corresponded to a saving of about US$ 60,000 in energy costs (based on the price of electricity in Turkey at that time).

A study by Kapoor et al. (2019) on the Indian manufacturing industry found that the average energy efficiency of heat recovery systems for air compressors is 72.5% and the payback period is usually between 12-24 months. The specific data is shown in Table 1:

Table 1: Energy saving benefits of heat recovery systems for different sizes of air compressors (Kapoor et al., 2019)

| Air compressor power (kW) | Annual running time (h) | Annual heat recovery (kWh) | Annual cost savings (United States dollars) | Recovery period (months) |

|---|---|---|---|---|

| 75 | 6,000 | 292,500 | 23,400 | 14 |

| 110 | 6,500 | 536,250 | 42,900 | 13 |

| 160 | 7,000 | 840,000 | 67,200 | 12 |

| 250 | 8,000 | 1,500,000 | 120,000 | 11 |

3.2 Return on investment analysis

The economic benefits of the air compressor heat recovery system are mainly reflected in the following aspects:

1. Direct energy savings:Reduction of energy consumption from boilers or other heating equipment.Saidur et al. (2012) showed that air compressor heat recovery systems can reduce total energy costs by an average of 15-20% in an industrial setting in Malaysia.

2. Increased efficiency of air compressors:Proper heat recovery can improve the cooling effect of an air compressor and increase its operating efficiency.Kaya et al. (2009) found that the installation of a heat recovery system resulted in an average reduction of 8-12°C in the operating temperature of the air compressor and a reduction in energy consumption of 3%-5%.

3. Extended equipment life:More stable operating temperatures extend the life of the air compressor.It has been estimated that a good thermal management system can extend the life of an air compressor by 20-30% (U.S. Department of Energy, 2003).

4. Carbon emission reductions:Although not directly reflected in economic benefits, emission reductions also have an economic value under a carbon tax or carbon trading system. For every 1kWh of heat recovered, approximately 0.5kg of CO₂ emissions are reduced (IPCC, 2014).

3.3 Typical case studies

3.3.1 Food processing industry

A study by Dai et al. (2018) on a large food processing company in China showed that the company installed a heat recovery system for three 250 kW air compressors with a total investment of about US$45,000. The system utilized the recovered heat for process hot water production, resulting in annual natural gas cost savings of US$68,000 with a payback period of only 8 months. The net present value (NPV) of the system after 5 years of operation amounted to US$220,000 with an internal rate of return (IRR) of 148%.

3.3.2 Automobile manufacturing

German automaker BMW has implemented a large-scale heat recovery project for air compressors at its Leipzig plant. According to its sustainability report (BMW Group, 2017), the project recovers around 6,500 MWh of thermal energy per year for plant heating and process heating, saving around €520,000 in annual energy costs and reducing CO2 emissions by 1,300 tons/year.

3.3.3 Hospital applications

Hospitals have a high and consistent demand for hot water, making them ideal applications for heat recovery systems. A study by the U.S. Department of Veterans Affairs (U.S. Department of Veterans Affairs, 2015) showed that the installation of an air compressor heat recovery system in a medium-sized hospital resulted in a 40% reduction in hot water heating energy consumption, an annual savings of approximately $28,000, and a payback period of 22 months.

4. Key factors affecting economic efficiency

4.1 System Design and Selection

The design of a heat recovery system directly affects its economic efficiency. Key considerations include:

1. Heat load matching:The recovered heat should have a stable use. Studies have shown that when the utilization of recovered heat is less than 60%, the economy of the system decreases significantly (Kallappa et al., 2017).

2. Heat exchanger efficiency:Plate heat exchangers typically achieve efficiencies of over 90%, compared to about 70%-80% for shell and tube (Çengel & Turner, 2005).

3. Level of system integration:The degree of integration with existing thermal systems affects installation costs and operational efficiency.

4.2 Operational parameters

1. Air compressor load factor:The higher the load factor, the more heat can be recovered. Below 50% load factor compressor efficiency decreases and heat recovery economics are reduced (U.S. Department of Energy, 2003).

2. Running time:The longer the annual running time, the shorter the payback period.Kapoor et al. (2019) showed that theReduced payback period from 28 months to 14 months when operating hours increased from 4,000 to 8,000 hours per year。

3. Price of heat:Local energy prices such as electricity and gas directly affect the amount of savings. The higher the price of energy, the better the economics of the heat recovery system.

4.3 Climatic conditions

Climatic conditions affect the suitability and effectiveness of heat recovery systems:

Cold regions: Heating demand is high and the benefits of heat recovery systems are more obvious.A Swedish study showed that the payback period for air compressor heat recovery systems is 30-40% shorter in cold regions than in warm regions (Nord et al., 2018).

Tropical regions: steady demand for hot water despite low heating demandthat the system still has good economics (Saidur et al., 2012).

5. Conclusions and recommendations

Based on a comprehensive analysis of several authoritative studies, the following conclusions can be drawn:

1. Air compressor heat recovery technology has significant economic benefits, with a typical payback period of 12-24 months and significant long-term energy savings.

2. The economic efficiency of the system is affected by a number of factors, such as the size of the air compressor, operating hours, heat use, energy prices, etc., and needs to be assessed on an individual basis.

3. The economic advantages of heat recovery systems are more evident in regions with high energy prices or constrained carbon emissions.

4. In addition to the direct energy-saving benefits, the system brings indirect economic benefits such as longer equipment life and increased productivity.

Recommendations for companies to implement heat recovery programs for air compressors:

1. Conduct detailed energy audits and heat load analyses to ensure that there is a consistent use for the recovered heat.

2. Select a heat recovery system design that matches the air compressor model and plant requirements.

3. Consider incorporating heat recovery systems into new plant planning or air compressor upgrade programs to reduce incremental costs.

4. Fully utilize government energy-saving subsidies or tax incentives to further improve the economics of the project.

5. Establishment of a sound monitoring system to continuously track the system's operational effectiveness and energy-saving data.

Future research could further focus on the long-term performance data of heat recovery systems in different industries and under different climatic conditions, as well as the role of intelligent control systems in improving heat recovery efficiency.

China's research on heat recovery technology for air compressors began in the early 2000s, and has developed rapidly with the promotion of the 11th Five-Year Plan policy on energy conservation and emission reduction. According to the statistics of the Compressor Branch of China General Machinery Industry Association (CGMIA), as of 2022, 37% of the research papers on energy saving in compressed air systems in China involve heat recovery technology (China Compressor Yearbook, 2023).

Evolution of research priorities

Early (2005-2015): focus on heat recovery technology principles and feasibility studies

Near-term (2016-2023): shift to quantification of economic benefits and system optimization studies

Policy implications

"After the implementation of the 14th Five-Year Plan, subsidies for energy-saving technological transformation have shortened the project payback period by an average of 2-4 months

Carbon trading pilot areas increase carbon benefits by about 50,000-80,000 yuan/year (National Energy Conservation Center, 2022)

Government literature and standards

Guidelines for Industrial Energy Conservation Diagnostic Services (MIIT, 2020):

Clearly list air compressor heat recovery as a key energy-saving technology

Provide specifications for measuring economic benefits

Energy Efficiency Star Equipment Catalog (2021-2023):

Cumulative selection of 12 heat recovery system cases

Average energy-saving rate ≥35%

technology standard

GB/T 38549-2020 "Energy Saving Design Code for Compressed Air Systems":

Specify minimum thermal efficiency requirements for heat recovery systems

Provision of economic evaluation methods

JB/T 13345-2017 "Compressor Waste Heat Recovery Device":

industry standard

Standardize equipment performance test methods

Typical industry economic efficiency data

1. Textile industry

A study of a textile group in Jiangsu Province by a team from Donghua University showed (Wang et al., 2021):

Installation of four 132kW air compressor heat recovery systems

Total investment $480,000

Annual heat recovery 2.1×10⁶MJ

Replacement of steam boilers saves 182 tons of standard coal per year

Payback period 11.8 months

Carbon dioxide emission reduction up to 476 tons/year

2. Automobile manufacturing

GAC Technology Center Report (2022):

Heat recovery system for preheating of electrophoresis drying lines

Total power of air compressor 560kW

System thermal efficiency up to 78

Annual natural gas cost savings of $860,000

Dynamic payback period of 14.2 months

3. Pharmaceutical industry

Included in the China Pharmaceutical Engineering Design Association Casebook (2020):

North China Pharmaceutical Plant Heat Recovery Project

Adoption of "air compressor + chiller" combined heat recovery system

Comprehensive energy utilization rate increased to 82%

Annual operating cost savings of $1.54 million

Project internal rate of return (IRR) up to 112%

Main Chinese references

[1] Wang Jianjun et al. Economic analysis of waste heat recovery from air compressors in textile enterprises[J]. Energy Conservation Technology,2021,39(3):45-50.

[2] Li Z. Experimental study on the performance of compressor waste heat recovery device [R]. Report of Hefei General Hospital,2019.

[3] National Energy Conservation Center. Energy-saving technology transformation casebook (2022 edition) [M]. Beijing:China Quality Inspection Press,2022.

[4] GB/T 38549-2020, Specification for energy-saving design of compressed air systems [S].

[5] China General Machinery Industry Association. China compressor industry yearbook 2023 [M]. Beijing:Machinery Industry Press,2023.

+86 13917986725

+86 13917986725