Technical Articles

Status and Prospects of Ductless Fume Hoods

I. Overview of ductless fume hoods

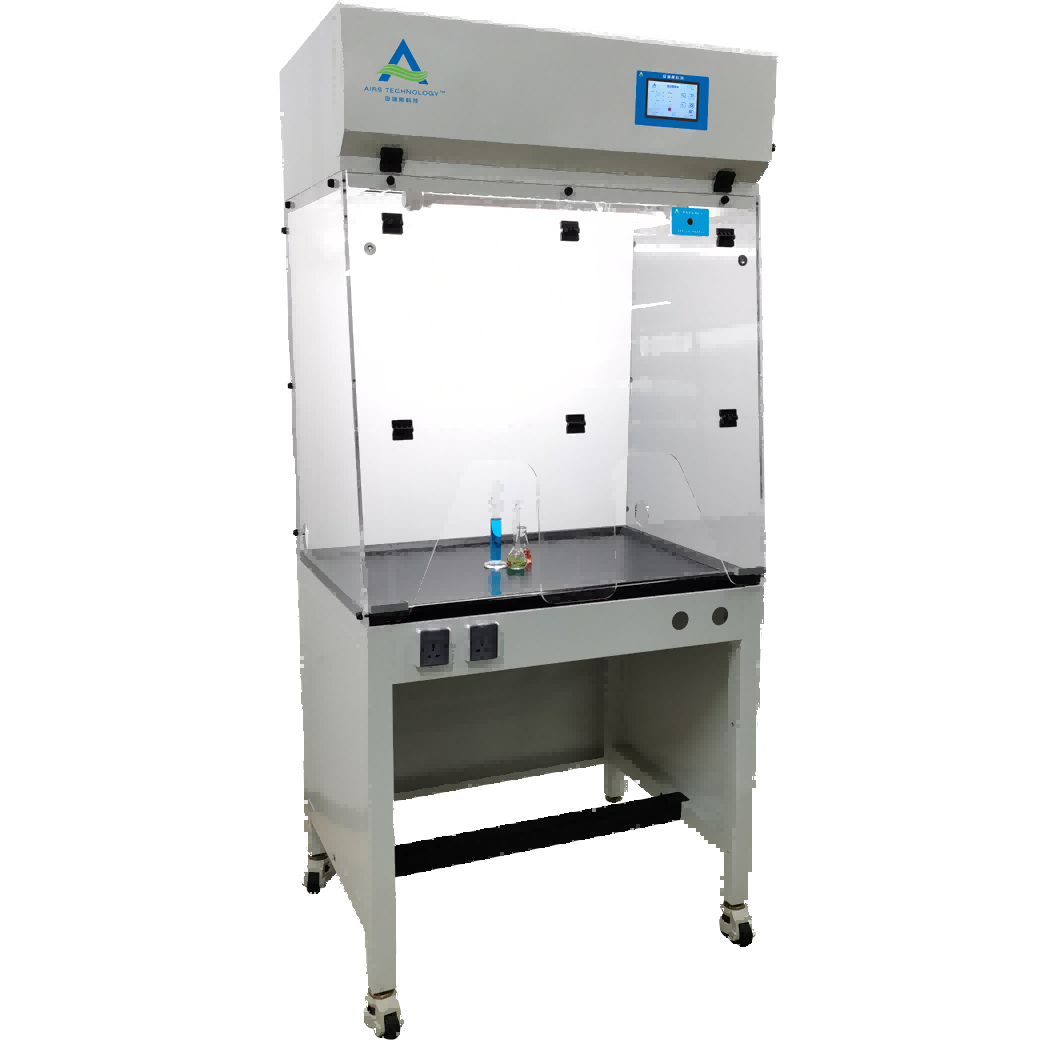

Ductless Fume Hoods, also known as filtered fume hoods orFume hoods, is an important innovation in the field of laboratory safety equipment in recent years. Unlike traditional ducted fume hoods, ductless fume hoods do not need to be connected to an external exhaust system; instead, they adsorb and purify harmful gases and particles generated during experiments through a built-in high-efficiency filtration system, and then recirculate the clean air back into the laboratory or discharge it in a limited manner.

According to the American Chemical Society's (ACS) 2018 Guide to Laboratory Fume, ductless fume hoods were first commercially available in the 1990s and were initially used primarily in teaching laboratories and specific industrial environments. As filtration technology has advanced, their applications have gradually expanded. The global ductless fume hoods market is growing at a CAGR of approximately 8% and is expected to reach a size of USD 450 million by 2025, according to a report by the National Institute for Occupational Safety and Health (NIOSH) 2020.

II. Technical comparison between ductless fume hoods and traditional fume hoods

1. Structural differences

Traditional ducted fume hoods consist of a cabinet, operating surface, exhaust system, and a network of ducts that are required to vent contaminants directly to the exterior of the building. According to the U.S. standard for fume hoods, ANSI/ASHRAE 110-2016, these types of fume hoods must maintain a steady face air velocity (typically 0.3-0.5 m/s) to ensure effective protection.

Ductless fume hoods, on the other hand, eliminate the need for complex ductwork and are mainly composed of cabinets, fans and filtration systems. According to the EU EN 14175-6:2019 standard, its core component is a high-efficiency adsorption filter, and common types include:

Activated carbon filters: for organic vapors

HEPA/ULPA filters: for particulate matter

Specialized chemical filters: for specific chemicals (e.g., acids, bases, mercury, etc.)

2. Principles of operation

Conventional fume hoods work through the principle of negative pressure to exhaust pollutants directly to the outside. The U.S. Environmental Protection Agency's (EPA) 2021 technical paper states that such systems consume an average of about 6,000-8,000 kWh of electricity per unit per year, mainly from maintaining the exhaust system in operation and make-up air treatment.

Ductless fume hoods utilize a "capture-absorb-circulate" model. Tests conducted by SEFA 2022 show that modern ductless fume hoods use only 30-40% of the fan energy of traditional models and require no additional air conditioning make-up air.

Third, the advantages of ductless fume hoods are analyzed

1. Installation flexibility

The Laboratory Design Institute (LDI) 2020 case study shows that ductless fume hoods cost 40-60% less to install than traditional models, with major savings in:

No plumbing required

No rooftop discharge facility required

No make-up air system modifications required

The University of California's 2019 Campus Laboratory Renovation Program reports that ductless fume hoods are virtually the only viable option in historic buildings or space-constrained locations.

2. Energy efficiency

The U.S. Department of Energy's (DOE) 2021 assessment report shows:

Conventional fume hoods: annual energy consumption per unit is about $800-$1200.

Ductless Fume Hoods: Annual energy consumption per unit is about $200-$400.

The Massachusetts Institute of Technology's (MIT) Sustainable Labs 2020 program achieved a 23% reduction in total lab energy consumption through ductless fume hood replacement.

3. Environmental friendliness

Traditional fume hoods emit pollutants directly into the atmosphere. According to EPA 2022 data, laboratory fume systems emit approximately 500,000 tons of VOCs annually in the U.S. Ductless fume hoods reduce emissions by more than 95% through adsorption filtration.

4. Special application advantages

The National Institutes of Health (NIH) Biosafety Guidelines for 2021 specifically state that HEPA-equipped ductless fume hoods are more effective at preventing cross-contamination than conventional models in biological laboratories up to BSL-2 level.

IV. Limitations of Ductless Fume Hoods

1. Filtering capacity limitations

The American Industrial Hygiene Association (AIHA) 2020 test report states that ductless fume hoods are highly dependent on suitability:

Chemical type: not applicable to highly concentrated acids, strong oxidizers, etc.

Frequency of use: Continuous use for more than 8 hours may result in premature saturation of the filter.

Compound combinations: mixing chemicals may reduce filtration efficiency

2. Monitoring requirements

Ductless fume hoods are required under OSHA 29 CFR 1910.1450:

Real-time filter saturation monitoring

Airflow Alarm System

Periodic performance verification records

3. Long-term cost considerations

While the initial investment is low, the Laboratory Safety Institute (LSI) 2022 cost analysis shows:

HEPA filter replacement cost: $500-$3000/year

Professional Disposal Fee: $200-$800/session

Certification Test Fee: $500-$1000/year

V. Consumables replacement cycle and reliability

1. Filter life

Average data provided by major manufacturers (Erlab, AirClean, Purair, etc.) in their 2021-2022 product brochures:

Filter type Average life (regular use) Replacement cost

General Purpose Activated Carbon 6-12 months $800-$1500

HEPA 2-3 years $500-$1000

Specialty Chemistry 3-6 months $1000-$3000

2. Actual utilization data

A report released in 2022 by Harvard University's Environmental Health and Safety Department tracked 87 ductless fume hoods on campus:

32% need to be replaced early (mainly due to the use of undeclared chemicals)

15% are still in use beyond the recommended cycle (but tests show a decrease in efficiency)

53% replaced within the recommended cycle

3. Reliability safeguards

To ensure reliability during the one-year replacement cycle, best practices include:

Installation of intelligent monitoring systems (e.g. Erlab's DFS system)

Restrictions on the list of permitted chemicals

Periodic (quarterly) performance testing

VI. Applicable industries and application prospects

1. The field of education

The American Journal of Chemical Education (JCE) 2021 survey shows:

85% of undergraduate teaching laboratories have adopted ductless fume hoods

Main uses: basic chemistry experiments, demonstration experiments

Annual savings: approximately $15,000-$30,000 per lab

2. Medical and life sciences

Recommended application scenarios according to NIH 2022 guidelines:

Pathology laboratory (formaldehyde treatment)

Pharmacy preparation (weighing of small doses of drugs)

Clinical testing (volatile reagent use)

3. Industrial quality control

Pharmaceutical industry (e.g. Pfizer, Merck) 2020-2022 sustainability report shows:

60% of new QC labs have hybrid systems (conventional + ductless)

Main applications: Rapid testing, sample preparation

Advantage: Reduced risk of cross-contamination

4. Emerging areas of application

The industry analysis report 2022 points out the growth points:

Electronics industry: semiconductor material handling

Forensic science: on-site testing equipment

Agricultural science and technology: pesticide research and development laboratories

VII. Technology development trends

1. Intelligent monitoring systems

New technology on display at Pittcon 2022:

Real-time mass spectrometry to monitor filter efficiency

AI predicts filter life

Blockchain Records Maintenance History

2. New filter materials

Research Directions for ACS 2021 Annual Meeting Report:

Metal Organic Frameworks (MOFs) materials

Nanofiber Composite Filter

Self-regenerating catalytic filters

3. Systems integration

Solutions showcased at LabDesign 2022:

Integration with Laboratory Information Management System (LIMS)

Emergency back-up filtration systems

Modular design for easy upgrades

VIII. Selection of recommendations and use of norms

1. Assessment of application scenarios

American Fume Hood Standards Council 2022 Recommended Decision Process:

Clarifying the list of chemicals

Assessment of frequency and duration of use

Calculating Total Cost of Ownership (TCO)

Verify compliance (especially local regulations)

2. Use of best practices

The International Laboratory Safety Organization (ILSO) 2021 guidelines emphasize:

Strictly limiting the use of chemicals beyond their designed range

Record type and amount of chemical per use

Periodic (at least semi-annually) performance testing

3. Maintenance norms

Maintenance intervals recommended by major manufacturers:

Daily: Check airflow indicators

Weekly: cleaning of work surfaces

Monthly: Checking the appearance of the filter

Annually: professional certification tests

IX. Conclusion

Based on available objective data and real-life application cases, ductless fume hoods do show significant advantages in specific application scenarios, especially in the fields of education, medical testing and industrial QC. Their energy-saving features, installation flexibility and environmental friendliness are in line with current trends in sustainable laboratory development.

However, technical limitations remain, especially when dealing with complex chemical combinations and high throughput applications. Annual filter replacement intervals are reliable under regulated conditions of use, but need to be supported by strict monitoring and management systems.

In the future, with technological advances in filtration materials and the popularization of intelligent monitoring systems, ductless fume hoods are expected to replace traditional models in more areas, but the complete replacement of ducted systems is still unrealistic in the foreseeable future. Laboratories should make a comprehensive technical and economic assessment based on specific needs when making a selection.

+86 13917986725

+86 13917986725