Technical Articles

Types, principles and application scenarios of interfacial tensiometers in detail

I. Overview of interfacial tension and its measurement significance

Interfacial tension is a physical phenomenon that exists at the interface between two immiscible liquids (liquid-liquid) or liquids and gases (liquid-gas), and is manifested as a tendency to contract due to an imbalance of intermolecular forces at the interface. This phenomenon is ubiquitous in nature and industrial production, from the water droplets on the lotus leaf to the oil driving process in oil extraction, interfacial tension plays a key role.

Accurate measurement of interfacial tension is important in many fields: in the petroleum industry, interfacial tension data directly affect the efficiency of tertiary oil recovery; in the pharmaceutical industry, the stability and absorption rate of pharmaceutical preparations are closely related to the interfacial properties; in the field of material science, the study of the wettability and adhesion of new materials requires accurate interfacial tension data; in the food industry, the stability of the emulsified products directly depends on the interfacial tension characteristics. tension properties.

With the development of science and technology, the interfacial tension measurement technique has been developed from simple mechanical methods to a variety of high-precision instrumental measurements, mainly including ordinary interfacial tensiometers, rotating drop interfacial tensiometers and dynamic bubble tensiometers and other types. Each of these instruments has its own characteristics and is suitable for different research scenarios and measurement needs.

2, Normalinterfacial tensiometer: Principles and Applications

Ordinary interfacial tensiometers (also known as static tensiometers) were the first class of interfacial tension measurement equipment developed, mainly including the Wilhelmy plate method, the Du Noüy ring method, the suspended drop method and the seated drop method. These methods are based on the principle of mechanical equilibrium, and the interfacial tension value is calculated by measuring the force or geometric parameter directly related to the interfacial tension.

The Wilhelmy plate method is one of the most classical measurement methods, proposed by the German scientist Wilhelmy in 1863. The method partially immerses a thin plate (usually made of platinum or glass) in a liquid and measures the tensile force exerted by the liquid on the plate. The interfacial tension γ can be calculated by the equation γ = F/(L-cosθ), where F is the measured force, L is the perimeter of the plate, and θ is the contact angle.Kumar et al. (2021), in a study published in Journal of Colloid and Interface Science, used the Wilhelmy plate method to accurately measure the interfacial tension between ionic liquids and water at different temperatures. The tension at the interface with water at different temperatures was accurately measured using the Wilhelmy plate method, which provides fundamental data for the application of new green solvents.

The Du Noüy ring method was introduced by French scientist Du Noüy in 1925 and uses a platinum ring to measure the maximum pulling force as it is pulled up from the liquid surface. Compared to the plate method, the ring method requires more complex correction factors but is more suitable for small volume samples.Zhang et al.'s (2020) study in Langmuir systematically investigated the synergistic effect of surfactant mixtures at the oil-water interface using the Du Noüy ring method, which provides a guide to the development of efficient emulsifiers.

The hanging drop method determines the interfacial tension by analyzing the shape of a droplet in another liquid or gas and is particularly suitable for high pressure and high temperature conditions. The method is based on the Laplace equation and the interfacial tension is calculated by fitting the droplet profile. In petroleum engineering, the hanging drop method is widely used to study interfacial properties under reservoir conditions. For example, Alvarez et al. (2019) reported in the journal Fuel the use of the high-pressure suspended droplet method to study the interfacial behavior of the CO2-crude oil system under reservoir conditions, which provides a key parameter for carbon capture and storage (CCS) technology.

The main advantages of common interfacial tensiometers are their simplicity, ease of operation and relatively low cost. However, they are often difficult to measure ultra-low interfacial tensions (<10-² mN/m) and have limited ability to track dynamic interfacial processes. These limitations have led to the development of more advanced rotating drop and dynamic bubble tensiometers.

III. Rotating drop interfacial tensiometer: a tool for ultra-low tension measurement

The Rotating Droplet Interfacial Tensiometer (RDIT) is a specialized device for measuring ultra-low interfacial tension (10-³-10-¹ mN/m) and is particularly suited for the study of surfactant systems, microemulsions and enhanced oil recovery (EOR) processes. The working principle is based on the theory proposed by Vonnegut (1942): in a capillary tube rotating at high speed, the denser phases move outward to form cylindrical droplets, and the interfacial tension can be calculated by measuring the droplet diameter.

The core equation of the rotating drop method is γ = Δρ-ω²-D³/32, where Δρ is the density difference between the two phases, ω is the rotational angular velocity, and D is the droplet diameter. The key advantage of this method is the ability to measure very low interfacial tension and to study the kinetic behavior of interfacial tension by adjusting the rotational speed.Chen et al. (2022) published a study in Energy & Fuels using the rotating droplet technique to systematically evaluate the ability of different surfactants to reduce the crude oil-water interfacial tension under high temperature and high salinity conditions, and screened out efficient formulations suitable for harsh reservoir conditions. The results of this study are summarized in the following table.

In the field of tertiary oil recovery, rotary drop technology plays an irreplaceable role. A large amount of crude oil remains in the pore space after conventional water drive, and by injecting a surfactant solution to reduce the interfacial tension between oil and water to an ultra-low level (on the order of 10-³ mN/m), the number of capillary tubes can be dramatically increased to drive out the residual oil.Wang's research team (2021) reported in detail in the Journal of Petroleum Science and Engineering how to optimize the surfactant formulation using a rotary drop interfacial tension meter to increase the recovery rate of an oil field by 15%. Engineering reported in detail how the surfactant formulation was optimized using a rotating drop interfacial tensiometer, which led to an increase in recovery of more than 15% in an oil field.

Microemulsion research is another important application area of the rotating drop technique. Microemulsions are thermodynamically stable nanoscale dispersed systems whose formation is closely related to ultra-low interfacial tension.The work of Liu et al. (2020) in Colloids and Surfaces A elucidated the mechanism of microemulsion formation by surfactant/co-surfactant synergism through rotating drop measurements coupled with phase behavior studies, providing a theoretical basis for the development of drug delivery systems. This provides a theoretical basis for the development of drug delivery systems.

The main limitations of the rotating droplet technique are the large sample volume requirement (usually several milliliters), the long measurement time, and the fact that it is not suitable for fast dynamic process studies. In addition, the method is difficult to apply for systems with near-neutral densities (Δρ≈0). These limitations have led to the development of dynamic bubble tensiometers to meet the need for fast dynamic measurements.

IV. Dynamic bubble tensiometry: a precision tool for capturing interfacial dynamics

Dynamic bubble tensiometers are powerful tools for studying the dynamic behavior of interfaces and are particularly suited to the study of adsorption kinetics of surface-active substances and interfacial rheology. These instruments track changes in interfacial tension over time by generating bubbles or droplets in a liquid and monitoring changes in their shape or pressure in real time.

The Dynamic Bubble Tensiometer has two main modes of operation:pendent drop/sessile drop mode and maximum bubble pressure methodMode. The former calculates dynamic interfacial tension by capturing the shape change of a suspended or seated drop with a high-speed camera and combining it with digital image analysis, while the latter determines the interfacial tension by measuring the maximum pressure of a bubble as it exits the capillary. Both methods have a time resolution of milliseconds and are capable of capturing fast interfacial processes.

The study of surfactant adsorption kinetics is an important application area for dynamic bubble tensiometry. The diffusion of surface-active molecules from the bulk phase to the interface and their rearrangement directly affects the stability of foams and emulsions.The work published in Soft Matter by Zhao's group (2021) systematically investigated the kinetics of the competitive adsorption of proteins with synthetic surfactants at the gas-liquid interface using the dynamic bubble method, providing new insights into the understanding of the interactions between biomolecules and surfactants. .

The dynamic bubble technique is also uniquely valuable in the study of respiratory physiology. The dynamic surface tension properties of lung surface-active substances (PS) directly affect respiratory function.Panda et al. (2019) reported in Scientific Reports the use of oscillating bubbles technique to study the dynamic behavior of PS under different pathological conditions, which provides new ideas for the diagnosis and treatment of respiratory distress syndrome.

Interfacial dilatational rheology is another important application direction of dynamic bubble tensiometry. By periodically compressing and expanding the interface, the elastic and viscous moduli of the interface can be studied. These parameters are essential for understanding the stability of foams and emulsions.A study by Xu et al. (2022) in the Journal of Colloid and Interface Science used the oscillating drop method to reveal a quantitative relationship between the viscoelasticity of interfacial protein films and the stability of emulsions, which provides theoretical guidance for the design of food and cosmetic emulsions.

The main advantages of dynamic bubble tensiometers are the high temporal resolution (up to milliseconds) and the small sample size required (down to microliters). However, these instruments are usually expensive, complex to operate and sensitive to vibration, requiring specialized operating skills and maintenance conditions.

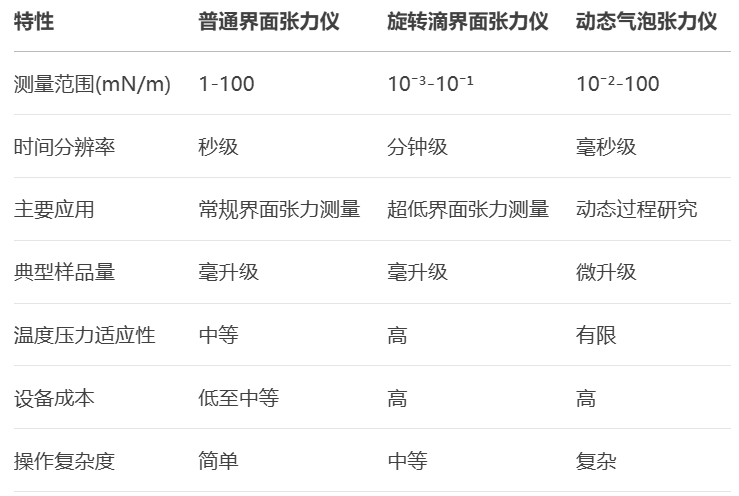

V. Comparison and selection guide of different types of interfacial tensiometers

In practical scientific and industrial applications, the selection of the right interfacial tensiometer depends on the specific measurement needs and research objectives. The table below summarizes a comparison of the key features of the three main types of interfacial tensiometers:

In practice, instrument selection should be based on the following considerations:

Interfacial tension range: for conventional systems (γ>1 mN/m), ordinary tensiometers are sufficient; ultra-low tensions need to choose the rotating drop method; dynamic studies require bubble tensiometers.

Time scale: slow processes (e.g., long time adsorption equilibrium) can be performed by normal or rotating drop method; fast dynamic processes (e.g., initial adsorption of surfactant) require bubble tensiometry.

Sample characteristics: precious or trace samples are suitable for the dynamic bubble method; high pressure and high temperature conditions prioritize rotating drop or high pressure suspension drop method.

Research objectives: simple interfacial tension measurements can be performed with common instruments; interfacial rheology studies require dynamic instruments; tertiary oil recovery applications often require rotating drop technology.

In practice, multiple techniques are often used in combination to obtain a more comprehensive understanding of interfacial properties. For example, in the development of a new surfactant, a researcher might first screen candidates using a normal tensiometer, then evaluate ultra-low tensiometric properties using a rotating droplet technique, and finally study adsorption kinetics using a dynamic bubble method.

VI. Frontier developments and outlook

Interfacial tension measurement technology continues to evolve, with several cutting-edge directions of interest:

The combination of microfluidics with interfacial tension measurements is opening up new possibilities. Microfluidic platforms can generate highly homogeneous arrays of microdroplets or bubbles, which, in combination with high-speed imaging and analytical algorithms, enable high-throughput screening of interfacial properties.Sattari et al. (2022) report in Lab on a Chip on an integrated microfluidic chip that can measure the interfacial tension of hundreds of microdroplets at the same time, dramatically improving screening efficiency.

Artificial intelligence techniques are being introduced into the field of interfacial tension measurement. Deep learning algorithms can improve the accuracy and speed of droplet profile analysis and even extract information from complex dynamic data that is difficult to obtain with traditional methods. Recent work published in Nature Communications Engineering by Lee's research team (2023) demonstrates how convolutional neural networks can simultaneously extract tension, rheology, and mass transfer parameters from dynamic interface images.

Extreme condition measurement techniques are also advancing. Application needs in fields such as deep-sea exploration, space science and technology, and the nuclear industry are driving the development of interface measurement techniques under high-pressure (>100 MPa), high-temperature (>200°C), and intense radiation conditions. These advances will have a direct impact on critical areas such as energy extraction, geothermal utilization and nuclear safety.

Multi-functional integrated systems have become a development trend. Modern high-end interfacial tensiometers are increasingly integrated with multiple measurement modes (e.g., simultaneous measurement of interfacial tension and rheology), multiple stimulation means (e.g., electric, magnetic, and optical field coupling), and in-situ characterization techniques (e.g., microscopy, spectroscopic coupling), which provide a powerful tool for the study of complex interfacial phenomena.

With the development of these technologies, interfacial tension measurement will become more accurate, efficient and informative, providing stronger support for basic research and application development in the fields of materials science, life science, energy technology and environmental engineering. For researchers and engineers, understanding the principles, characteristics and application scenarios of different interfacial tensiometers will help to select the most suitable tool to solve practical problems and promote technological advances in related fields.

+86 13917986725

+86 13917986725