Technical Articles

Critical Applications of Temperature Measuring Paper in the Food, Steel and Transportation Industries and the Auxiliary Role of Temperature and Humidity Loggers

summaries

This paper comprehensively explores thethermometer paperThe value of applications in key industries such as food processing, steel manufacturing and transportation logistics. As a simple, economical and efficient temperature monitoring tool, temperature measuring paper provides intuitive temperature records through irreversible color change reaction, and plays an irreplaceable role in quality control and safety assurance in various industries. The article analyzes in detail the specific application scenarios, advantageous features, and synergistic use strategies with temperature and humidity recorders of temperature measuring paper in different industries, which provides practical technical references and application guidance for practitioners in related industries.

bywordThermometer paper; Temperature and humidity monitoring; Food processing; Steel manufacturing; Cold chain transportation; Quality control

introductory

In modern industrial production and services, accurate temperature monitoring is a key component in ensuring product quality, production safety and process compliance. As a simple yet effective temperature monitoring tool, temperature measuring paper is widely used in a variety of industries such as food, steel, and transportation due to its ease of use, low cost, and intuitive results. In this paper, we will discuss the technical principles of temperature measuring paper, different types and their specific applications in various industries, as well as analyze the auxiliary role of temperature and humidity recorders in the temperature monitoring system, to provide comprehensive technical references and application guides for the relevant industries.

I. Technical overview of temperature measuring paper

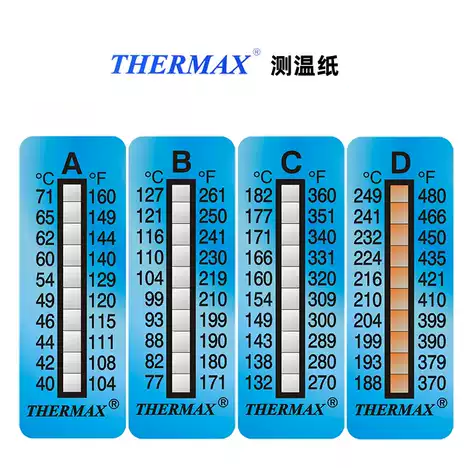

Temperature measuring paper is a special functional material that records temperature changes through chemical or physical reactions. Its core working principle is based on the irreversible color change characteristics of temperature-sensitive materials, when the ambient temperature reaches or exceeds the preset threshold, the specific area on the temperature measuring paper will undergo a significant color change, so as to visually display the temperature status. Depending on the measurement principle and material composition, temperature measuring paper can be divided into liquid crystal type, chemical color change type and thermal type, etc., each of which has its own specific temperature response range and applicable scenarios.

The main advantages of temperature measuring paper are its simplicity of use, cost-effectiveness and reliability. In contrast to electronic temperature measurement devices, temperature paper requires no power supply and no complexity to monitor temperature by simply attaching it to the surface of the object to be measured. At the same time, the paper's irreversible color change reaction provides a permanent record of temperature, which is important for quality traceability and compliance audits. However, there are some limitations, such as relatively low accuracy and the inability to provide a continuous temperature record, which makes it necessary to use it in conjunction with other temperature measurement devices in certain high-precision application scenarios.

Second, the food industry in the application of temperature measuring paper

In the field of food processing and storage, temperature control is a key factor in ensuring food safety and quality. Temperature measuring paper is widely used in baking, sterilization, cold chain and other aspects. In the baking process, temperature measuring paper can help operators to confirm whether the temperature in the center of the food reaches the safety standard; in the sterilization process, specific high temperature temperature measuring paper can be used to verify that the temperature of the sterilization equipment meets the standard; and in the cold chain logistics, temperature measuring paper is used to monitor the temperature abnormality in the transportation process.

The food industry has special requirements for temperature measuring paper, including food safety approvals, temperature range suitability and response times. For example, temperature measuring paper for direct food contact must comply with FDA or other relevant food safety standards; different food processes require different temperature ranges; and some rapid processes require fast-response temperature measuring paper products. Typical applications include center temperature testing of baked goods, sterilization verification of canned foods, and transport temperature monitoring of frozen foods.

Third, the application of temperature measuring paper in the steel industry

Steel production is a complex industrial process involving extreme high temperature environments, requiring precise temperature control at every step of the process, from iron and steelmaking to rolling and molding. Temperature measuring paper is mainly used in the steel industry for equipment surface temperature monitoring, process temperature verification and quality control. For example, in the continuous casting process, the paper is used to monitor the surface temperature distribution of the billet; in the heat treatment process, the paper is used to verify that the workpiece reaches the preset heat treatment temperature.

The steel industry's requirements for temperature measuring paper are focused on high temperature tolerance, fast response and immunity to interference. Due to the harsh environment of steel production, temperature measuring paper needs to be able to withstand high temperatures, dust and electromagnetic interference. Compared to electronic devices such as infrared thermometers, the advantages of temperature measuring paper in the steel industry are its low cost, simplicity of use and immunity to electromagnetic interference, but the disadvantage is that it is unable to provide real-time temperature data and continuous temperature profiles. Typical application scenarios include blast furnace system temperature monitoring, rolling mill temperature control and heat treatment process validation.

IV. Application of temperature measuring paper in the transportation industry

In the transportation of temperature-sensitive goods such as pharmaceuticals and food, temperature monitoring is a key link to ensure product quality and safety. Temperature measuring paper is widely used in cold chain transportation to record the temperature changes during the whole transportation process, which is especially suitable for various transportation modes such as air, sea and land transportation. Through the reasonable arrangement of temperature measuring points, temperature measuring paper can effectively monitor whether the goods experience temperature exceeding the standard during transportation.

The main needs of the transportation industry for temperature measuring paper include wide temperature range coverage, long-term stability and environmental adaptability. Different goods require different temperature ranges, and some special pharmaceuticals even require ultra-low-temperature paper; at the same time, long-distance transportation requires that the paper be stable over long periods of time; in addition, vibration and humidity variations in the transportation environment also pose a challenge to the performance of temperature measurement paper. The advantages of paper over data loggers are low cost, no maintenance and intuitive results, but it does not provide a continuous temperature and humidity profile. Typical applications include vaccine transportation temperature monitoring, frozen food cold chain validation and chemical transportation safety monitoring.

V. Synergistic application of temperature and humidity recorders and temperature measuring paper

Temperature and humidity loggerIt is an electronic monitoring device that can continuously record changes in environmental temperature and humidity and store relevant data for subsequent analysis. Compared with the temperature measurement paper, temperature and humidity logger has the advantages of continuous data, high accuracy, remote monitoring, etc., but its cost is higher and requires regular maintenance. In practical applications, temperature and humidity recorders and temperature measuring paper are often used in conjunction, to play their respective advantages.

In the food industry, temperature and humidity loggers are used for real-time monitoring of cold storage environments, while pyrometric paper is used for temperature verification of individual packaged products; in the steel industry, loggers monitor the ambient temperature of the shop floor, while pyrometric paper is used for point-temperature detection of specific equipment; and in the transportation industry, the loggers provide the full temperature and humidity profile, while pyrometric paper is used as a means of back-up and verification. This synergistic use model ensures comprehensive monitoring while providing a cost-effective solution.

VI. Conclusion

As a simple and practical tool for temperature monitoring, temperature measuring paper plays an irreplaceable role in industries such as food, steel and transportation. Its simplicity, economy and reliability make it an important tool for quality control and safety management. With technological advances, the future of temperature measuring paper will develop in the direction of higher precision, more intelligent and more environmentally friendly, while the combination with the Internet of Things (IoT) technology will also expand its application boundaries. Various industry practitioners should be based on their own needs, a reasonable choice of temperature measurement paper products, and consider the synergistic use of temperature and humidity recorders and other equipment, to build a comprehensive and efficient temperature and humidity monitoring system.

+86 13917986725

+86 13917986725